In the world of automation, one size rarely fits all. Every industry, and every business within it, faces its own unique workflow, spatial limitations, and evolving requirements. That’s where modular robotics is making a difference by offering adaptable, configurable solutions that can grow and shift with operational demands.

Whether it's manufacturing, logistics, warehousing, or commercial services, modular robotics allows businesses to adopt automation on their own terms piece by piece, task by task.

Modular robots are systems built from interchangeable units or components that can be rearranged, expanded, or upgraded without replacing the entire machine. This might include:

The key benefit is adaptability. A single robot can be configured today for product handling, tomorrow for packaging, and later modified for inspection without major reinvestment.

Traditional robots are often fixed-function. They’re built to perform one task within a defined environment. For many businesses, that level of specialisation limits scalability and responsiveness.

Modular robotics turns that approach on its head. It introduces flexibility into automation with benefits like:

For businesses that expect change, seasonal shifts, layout updates, or product line expansion, modular automation offers a strategic advantage.

Autonomous mobile robots (AMRs) with modular payloads are being used to carry parcels, tow carts, or scan shelves depending on current operational needs. Modules can be swapped on-site within minutes, keeping downtime to a minimum.

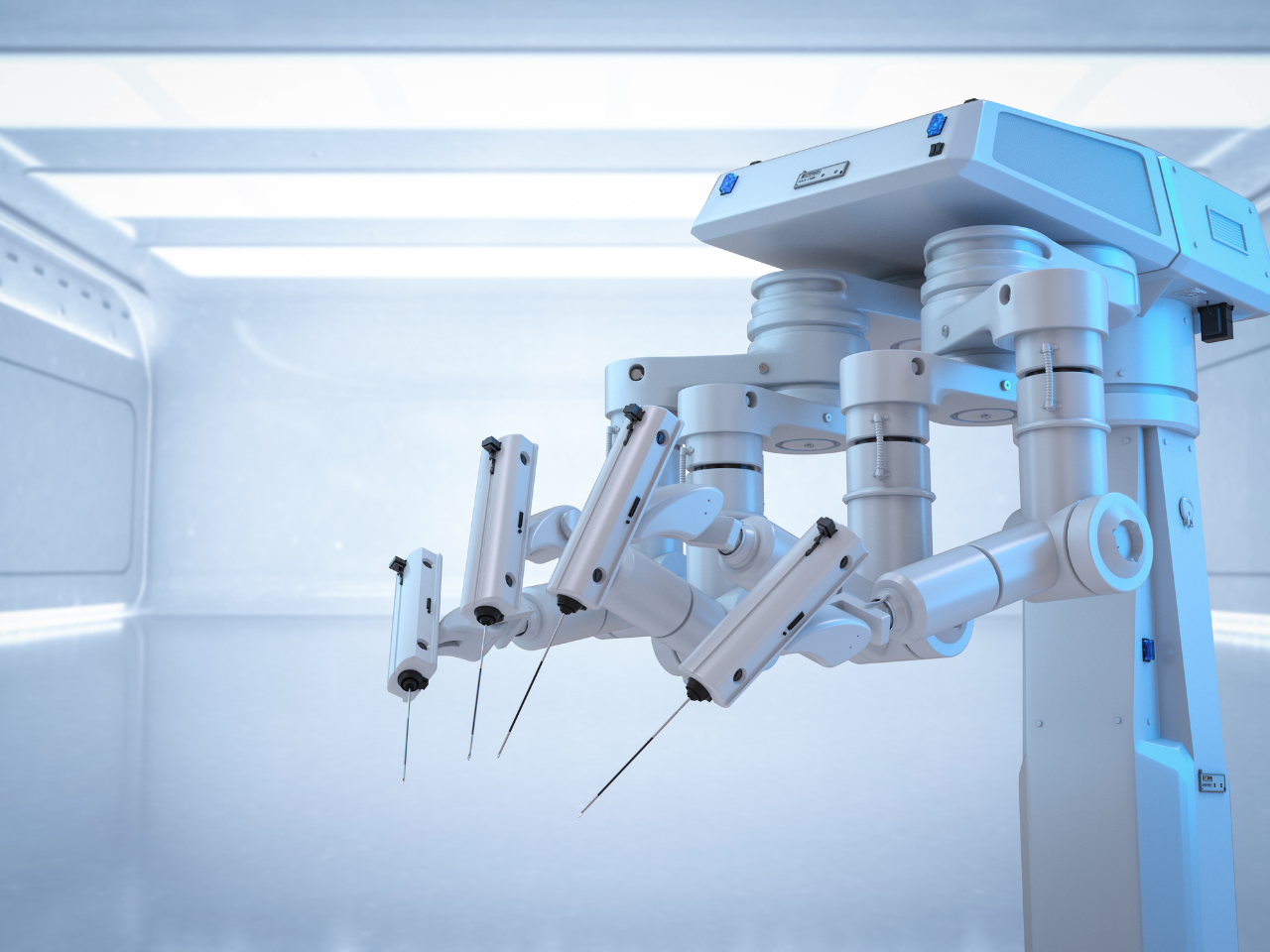

Robotic arms fitted with modular tools can alternate between welding, assembly, inspection, or packaging. This allows small and medium manufacturers to automate multiple tasks without separate dedicated systems.

A cleaning robot used in a commercial facility today can be adapted tomorrow to service a warehouse or industrial plant. Modular units may include water tanks, brushes, UV sanitisation modules, or vacuum systems, all swappable depending on the application.

In universities and research labs, modular robots provide a platform for experimenting with different technologies, sensors, and functions. These systems allow for rapid prototyping and reconfiguration without full system rebuilds.

While modular robotics is versatile, it’s not always the best option for highly specialised or high-speed applications. Before integrating modular systems, assess:

A proper planning phase ideally with a supplier or integrator familiar with modular platforms can ensure a successful deployment.

As industries shift toward agile production, short-run manufacturing, and responsive logistics, the demand for modular, reconfigurable robots will only grow. These systems allow businesses to automate without locking themselves into a single-purpose setup. For companies navigating rapid change, modular robotics offers something rare in industrial automation and freedom to adapt.